Dairy

constituents, notably the proteins and peptides, provide food companies

with a rich selection of potential ingredients for functional foods and

drinks. Dairy proteins and peptides provide desirable features such as

physical functional traits, nutritional qualities, and an increasing

array of substantiated bioactivities. The challenge for science and

technology has been to isolate these ingredients in a cost-effective

manner whilst maintaining their inherent functional and nutritional

traits. Continuous simulated moving bed chromatography (CSEP) provides

a solution and has been developed for the isolation of a number of milk

and whey-derived protein and peptide ingredients for use in the

functional food, sports nutrition and health foods markets. The

technology has several advantages over conventional chromatography

including efficiency, productivity and flexibility. In a ‘world-first'

for the Australian dairy industry, CSEP technology has been

successfully adapted for the manufacture of dairy ingredients enriched

in lactoferrin, glycomacropeptide and/or ß-lactoglobulin.

Dairy

constituents, notably the proteins and peptides, provide food companies

with a rich selection of potential ingredients for functional foods and

drinks. Dairy proteins and peptides provide desirable features such as

physical functional traits, nutritional qualities, and an increasing

array of substantiated bioactivities. The challenge for science and

technology has been to isolate these ingredients in a cost-effective

manner whilst maintaining their inherent functional and nutritional

traits. Continuous simulated moving bed chromatography (CSEP) provides

a solution and has been developed for the isolation of a number of milk

and whey-derived protein and peptide ingredients for use in the

functional food, sports nutrition and health foods markets. The

technology has several advantages over conventional chromatography

including efficiency, productivity and flexibility. In a ‘world-first'

for the Australian dairy industry, CSEP technology has been

successfully adapted for the manufacture of dairy ingredients enriched

in lactoferrin, glycomacropeptide and/or ß-lactoglobulin.

Geoffrey took a leading role in the introduction and development of this technology, including management of technology assessment, process development, validation, up-scaling and technology transfer, and aspects of commercialisation. He also took a key role in the creation and leadership of a science/technology-business partnership, which rapidly established the potential of the technology and the first of several commercial applications in the Australian dairy industry.

Recaldent™

is

a natural milk-derived ingredient very effective in reducing the

incidence of dental caries and promoting oral healthcare. Recaldent™

is isolated from the major milk protein – casein – and is highly

enriched in phosphopeptides. During the manufacturing process these

phosphopeptides are complexed with calcium and phosphate, and this

complex is then dried to form the Recaldent™ ingredient. Animal and

human clinical trials have demonstrated the highly efficacious

properties of Recaldent™ in both preventing and repairing dental

caries. This ingredient is suitable for inclusion in a range of foods

and beverages, as well as personal oral care products. Such products

include functional chewing gum available

in the USA, Japan and other parts of the world, and professional

products for dentists.

Recaldent™

is

a natural milk-derived ingredient very effective in reducing the

incidence of dental caries and promoting oral healthcare. Recaldent™

is isolated from the major milk protein – casein – and is highly

enriched in phosphopeptides. During the manufacturing process these

phosphopeptides are complexed with calcium and phosphate, and this

complex is then dried to form the Recaldent™ ingredient. Animal and

human clinical trials have demonstrated the highly efficacious

properties of Recaldent™ in both preventing and repairing dental

caries. This ingredient is suitable for inclusion in a range of foods

and beverages, as well as personal oral care products. Such products

include functional chewing gum available

in the USA, Japan and other parts of the world, and professional

products for dentists.

Recaldent™ was developed in a project involving several partners, including CSIRO, Melbourne University and Bonlac Foods (now Fonterra). Geoffrey took a leading role in bringing together this successful partnership, and he also managed the process development, validation, up-scaling and technology transfer, and aspects of the commercialisation.

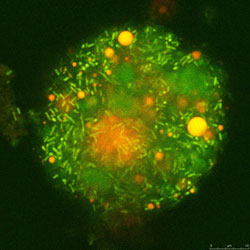

MicroMAX® MICROENCAPSULATION TECHNOLOGY

MicroMAX®

is a simple but clever microencapsulation

technology, which uses only natural food materials and standard food

processing equipment, for protection of sensitive bio-functional

ingredients , for their successful delivery into functional foods and

drinks, and potentially for their targeted delivery to particular

points in the gastrointestinal tract. MicroMAX® is a patented platform

technology that relies upon the reaction between a protein or peptide

(with free amino group(s)) and a carbohydrate (containing a reducing

sugar) to form a very effective encapsulation matrix with exceptional

film-forming and antioxidant properties. MicroMAX® was initially

developed and optimised for encapsulation of fish oil, but has

subsequently been adapted to the protection of other essential oils,

oil-soluble bioactive components (e.g. vitamin E) and probiotic

bacteria.

MicroMAX®

is a simple but clever microencapsulation

technology, which uses only natural food materials and standard food

processing equipment, for protection of sensitive bio-functional

ingredients , for their successful delivery into functional foods and

drinks, and potentially for their targeted delivery to particular

points in the gastrointestinal tract. MicroMAX® is a patented platform

technology that relies upon the reaction between a protein or peptide

(with free amino group(s)) and a carbohydrate (containing a reducing

sugar) to form a very effective encapsulation matrix with exceptional

film-forming and antioxidant properties. MicroMAX® was initially

developed and optimised for encapsulation of fish oil, but has

subsequently been adapted to the protection of other essential oils,

oil-soluble bioactive components (e.g. vitamin E) and probiotic

bacteria.

Geoffrey has provided strategic input regarding design of the research program. He has also developed a large number of business relationships with local and global companies interested in using MicroMAX® in their products, fostered these relationships, and managed license negotiations based on protected bioactive, end-use application, and geographic region.

Versagel™ is a natural and

healthy fat mimetic/substitute developed and patented by CSIRO to

facilitate the production of reduced-fat foods for the growing

health-conscious market. This ingredient is a premix powder formulated

to contain dairy protein and hydrocolloids that can be used to replace

fat in manufactured foods. Versagel™ can be used to produce a range of

novel reduced-fat meat, seafood, bakery and dairy products. By changing

the formulation, the appearance, texture, flavour and mouth-feel of

Versagel™ can be tailored for specific food applications. This

characteristic enables food processors to develop new product

formulations and styles with desirable sensory and nutritional

properties while significantly reducing their fat content.

Versagel™ is a natural and

healthy fat mimetic/substitute developed and patented by CSIRO to

facilitate the production of reduced-fat foods for the growing

health-conscious market. This ingredient is a premix powder formulated

to contain dairy protein and hydrocolloids that can be used to replace

fat in manufactured foods. Versagel™ can be used to produce a range of

novel reduced-fat meat, seafood, bakery and dairy products. By changing

the formulation, the appearance, texture, flavour and mouth-feel of

Versagel™ can be tailored for specific food applications. This

characteristic enables food processors to develop new product

formulations and styles with desirable sensory and nutritional

properties while significantly reducing their fat content.

Geoffrey has negotiated license and option arrangements for Versagel™ on the basis of end-use application and geographic region. The technology has been licensed in Australia, New Zealand and the Middle East, and is pending in the USA. Geoffrey has also assisted end-users to tailor and trouble-shoot the application of Versagel™ in their food products, leading to a range of successful commercial outcomes, including for example Hoffy Extra Lean Beef Franks in the USA .

NON-THERMAL PROCESSING TECHNOLOGIES

Increasing consumer

demands for safe, natural and less

processed foods and drinks prompted the establishment of the Innovative

Foods Centre (IFC) in 2001 (with further expansion in 2005), a research

consortium between CSIRO, Food Science Australia and other

institutions, for the study, development and commercialisation of

alternative non-thermal food processing technologies in Australia. Such

technologies included high-power ultrasound, high pressure, pulsed

electric field, microwave and cool plasma. High pressure processing was

considered a key technology. Based upon work at the IFC, an Australian

‘start-up' has commenced commercial high

pressure processing of juices for sale in Australia and South-East Asia

Increasing consumer

demands for safe, natural and less

processed foods and drinks prompted the establishment of the Innovative

Foods Centre (IFC) in 2001 (with further expansion in 2005), a research

consortium between CSIRO, Food Science Australia and other

institutions, for the study, development and commercialisation of

alternative non-thermal food processing technologies in Australia. Such

technologies included high-power ultrasound, high pressure, pulsed

electric field, microwave and cool plasma. High pressure processing was

considered a key technology. Based upon work at the IFC, an Australian

‘start-up' has commenced commercial high

pressure processing of juices for sale in Australia and South-East Asia

Geoffrey took a key role in establishing the IFC, including co-authorship of successful grant proposals and business plans that attracted >$6 m in establishment costs. He was also very active in creating commercial awareness of the potential of non-thermal processing technologies, building robust business relationships, and negotiating equipment supply and maintenance arrangements often with overseas suppliers.